Speeds in excess of 200mph, the smell of burning rubber and the growl of an engine at full throttle.

Where else could you experience the kind of adrenaline-fuelled action seen in the high-tech, high-speed world of Formula One?

Drivers are hailed as celebrities and the likes of Lewis Hamilton and Jenson Button are have sped their way into living rooms across the country with their title wins.

But F1 drivers would be nothing without a team of thousands behind them; researching, developing and building the best that technology has to offer.

And just like drivers, mechanics start from the bottom to learn their trade and apply it at the basic level in order to rise to the very top of the sport.

International event Formula Student (FS) provides just that opportunity, acting as a crucial stepping-stone onto the motorsport ladder for technically-minded petrolheads.

The event attracts interest from across the globe and gets university students designing and building their own living, breathing racing machines.

TEAM POWER: Last year’s car is put through its paces at Silverstone

Formula Student is held in such esteem that the sport’s most famous Mancunian, Ross Brawn – who is known for his success in F1 with Michael Schumacher as well as a team bearing his own name – is a patron for the event.

“The key to the event – and the reason those who take part so often end up working in F1 and at the world’s leading engineering firms – is that it offers the practical experience which is so important in the professional world,” said Brawn.

“During my career in Formula One, we often employed people who had taken part in Formula Student.

“It is perhaps the best opportunity students have to be truly innovative, to ‘think outside the box’ and come up with practical engineering solutions which may one day be used within the automotive industry.”

The technical guru holds an honorary engineering doctorate at Manchester Metropolitan University and the university will once again on the grid in the event from July 9-13 at Northamptonshire circuit Silverstone, known as ‘home of motorsport’.

MM have taken a look at what is required of the engineers of the future and spoke to Stuart Nicholls, Co-Team Principle of MMU’s project.

“It is a student-led and designed competition where we have to design and build a single-seater race car from scratch each year,” said Stuart, who is currently a final-year Automotive Engineering student and competing in his third FS event.

“You spend a lot of time on the course doing the designing – but doing this project is where you put all that into practice.”

Along with fellow Team Principle Yousuf Khan, they are leading a group of around 30 students to undertake the daunting task of building a racing car from scratch.

Many people would consider the prospect of building a race car and going racing exhilarating but, as Stuart explains, it’s not all fun and games.

“We cost every bit of the car from material, processing and assembly,” continued Stuart.

“Then we have to do a business presentation to a panel of experts and sell our concept to them as though we were trying to sell it to the amateur race market.”

The university is just one of around 60 UK entries to be taking part in the event, which will see 135 competitors from 33 countries all revved up and ready to go on the day.

Every area of the car is inspected in fine detail by industry professionals and marked on various criteria such as style and ingenuity.

There is also a second side of marking – performance, which includes a series of tests from acceleration to sprint and endurance to skidpan.

Each area is marked individually and the team with the highest combined score by the end of the week will be crowned champions.

Currently, the FS project is not part of the curriculum at MMU and Sam Andrews, a third-year Mechanical Engineering student, can see the positives of going that extra mile and taking part in the venture.

“It’s very different from the course,” he said.

“The course is mostly paperwork and theoretical maths but FS gives you the chance to work in a team and also get your hands dirty.

“It’s much more hands-on and is enjoyable but also worthwhile with the experience.”

Sam knows more than most the opportunities it can open up, having spent time with the Caterham Formula One team.

“It’s absolutely better to have the experience,” Sam enthused.

“If people see you have done it, they understand what you have been through and the experience you have gained from it. It’s really valuable.”

This is a message echoed by Formula Student Chairman Jon Hilton, who is proud that the event is held in such high regard by industry professionals.

RACE AGAINST TIME: The cars take five months to design but are assembled in three weeks

“We know from experience that taking part in FS is now seen as almost a pre-requisite for those wanting to work in automotive engineering, motorsport and wider industry as a whole,” he said.

“At its heart, FS remains an educational competition, and it’s great to see this reflected by the esteem in which it’s held.”

Juggling academic work with the task of building a car can be tough – as can the communication between the various areas of the car, which include chassis and suspension, engine and drivetrain, frame and body and electrics.

Adam Wilson, a first-year Mechanical Engineering student, admits it is a challenge but hopes that the sacrifices will be worthwhile in the long run.

“It’s a very steep learning curve but I think the main things you learn is time management and that you need to communicate with the rest of the team in order to end up with a good final product,” he said.

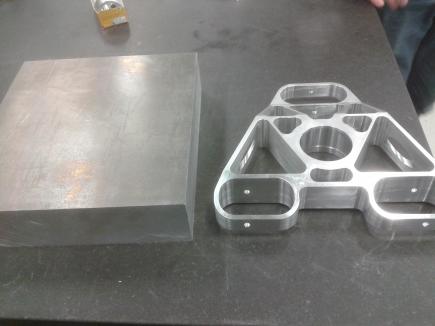

PIECE OF THE PUZZLE: This suspension upright (r) was cut from a £200 aluminium block (l)

“For example, if someone is designing the suspension and I’m designing the steering, if we don’t talk to each other then we’ll end up with things clashing so getting a good team structure is probably the main thing.

“It’s definitely something I will carry on into my second and third year.”

All design work will have been finalised and the building of the car, which will house a Yamaha R6 engine capable of speeds of up to 80mph, will cost around £25,000 – most of which is supported by the university itself.

SCHOOL OF SPEED: The cars can reach up to 80mph

Although the event is supposed to be solely for students, this has been a contentious area in recent years.

“A lot of German university teams are really well funded from car manufacturers,” explained Sam.

“The thesis is most of the work should be done by students but some of the other teams seem to get a lot of the work done by professionals.

“It’s a bit of an argument between people about this, whether you see the competition there as something to win or a learning experience for the students, so it depends on your outlook.”

Mr Hilton argues that money is not a factor when deciding who wins the event however.

“Some teams will always be better funded than others – there’s very little we can do about that,” he said.

“Universities will always have different ideas about how much funding to allocate and what percentage of the curriculum – if any – FS will represent.

“However, FS is, and will always be, an engineering competition which rewards innovation, engineering expertise and strong teamwork.

“Our judges are not looking for the most expensive cars, but the quality of the engineering behind them.”

STARTER’S ORDERS: Work has begun on the chasis for this year’s car

And second-year Automotive Engineering student Callum Scullon also insists it doesn’t matter about winning – but gaining experience for the future which is the main purpose of the project.

“It does kind of sour the competition but at the same time it doesn’t really matter where you come, it’s all about the learning experience,” he said.

After finishing just outside the top-70 last year, the Manchester squad are hoping for a top-30 finish this time round.

Whatever the result, the road to the top is a long and windy one – but the FS scheme is one that is likely to produce the next Colin Chapman and Adrian Neweys of the future.

And the FS chairman Hilton believes students should jump at the chance to take part.

“I’d say do it, without hesitation,” he enthused.

“It’s mentally and physically demanding, frustrating at times and really does push students to the limits of their engineering capabilities – but it’s also a brilliant opportunity to create and innovate as part of a close-knit team, forging friendships and experiences you’ll remember forever.”